VIP member

Ball type THK linear guide slider RSR9M1N

Advantages and features: THK linear guide RSR9M1N applies a mechanical or hydraulic force (unloading force) to the moving parts in the opposite direct

Product details

Advantages and Characteristics:THK linear guide rail RSR9M1N applies a mechanical or hydraulic force (unloading force) to the moving parts in the opposite direction of the guide rail load, offsetting some of the load on the guide rail, thereby maintaining direct contact between the guide rail surfaces and reducing the pressure on the guide rail working surface. The unloading force is generally taken as about 2/3 of the total gravity acting on the moving parts.

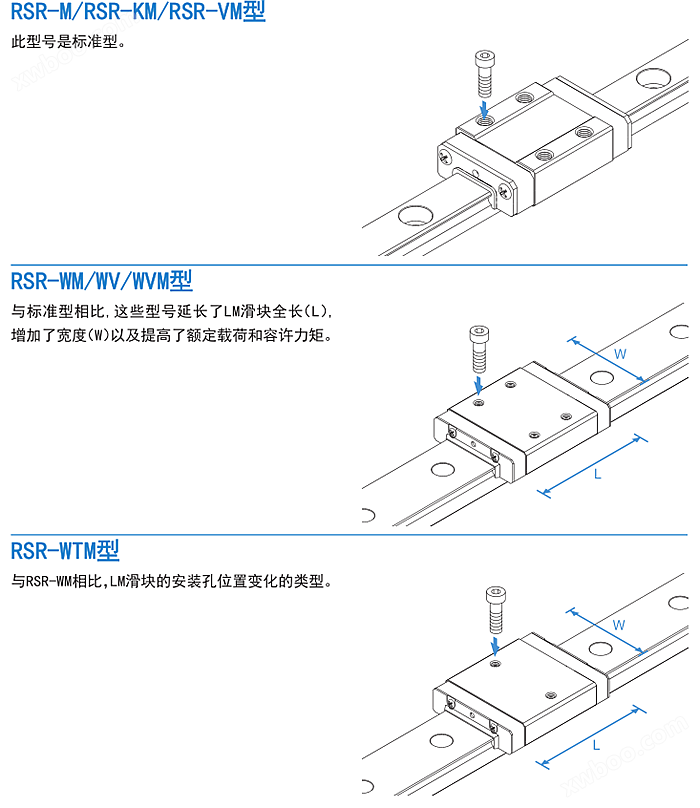

In RSR and RSR-W rolling guides, steel balls roll along two columns of precision ground rolling surfaces on the LM track and LM slider; By assembling the end cover plate on the LM slider, the steel ball column is cyclically moved.

The steel ball circulates in a miniaturized design, allowing for infinite linear motion without travel restrictions. The shape of the LM slider is designed to have high rigidity within a limited space, and by cooperating with large-diameter steel balls, it can achieve high rigidity in all directions.

Ultra miniaturization design

In the limited stroke types of cross roller guides and linear rolling units, the cage is most prone to problems, while in the RSR/RSR-W type, the cage does not shift, thus achieving a highly reliable and compact linear motion system.

Can bear loads in all directions

These models can carry loads in all directions, and for small torque loads, single axis guide rails are sufficient. In particular, the RSR-W type has increased the effective number of steel balls, widened the LM track amplitude, and improved the rigidity against torque. Therefore, compared to a pair of parallel linear bearings, it achieves a more compact structure and more durable linear motion.

Stainless steel type is also available

LM sliders, LM rails, and steel balls can also be made of stainless steel.

Places where a pair of linear bearings are used

Unlike using a pair of linear bearings, the RSR-W type can be used on a single axis, saving space.

Due to the addition of load steel balls in each column and the widening of LM sliders and LM tracks in the RSR-W type, high rigidity is achieved for cantilever loads.

Only using bolts to install LM tracks can achieve the required accuracy, thus reducing assembly time.

Places where cross roller units are used

Even when using the holder vertically, there will be no displacement and it can perform infinite linear motion.

No need for difficult gap adjustment, it can achieve smooth motion without gaps for a long time.

Due to the wide amplitude of the LM slider, this model can be used as a micro workbench without any modification.

The RSR type adopts Gothic arch grooves on the shape of its steel ball rolling surface. Therefore, when used in parallel with two axes, if there is an accuracy error in the installation surface, it will increase the rolling resistance and have an adverse effect on the smoothness of the guide rail movement.

When it is difficult to achieve satisfactory accuracy on the installation surface in the location where this model is used, we recommend using RSR... A type (semi standard type), where the steel ball rolling surface has circular grooves. (However, please avoid using it on a single axis).

THK linear guide rail RSR9M1N applies a mechanical or hydraulic force (unloading force) to the moving parts in the opposite direction of the guide rail load, offsetting some of the load on the guide rail, thereby maintaining direct contact between the guide rail surfaces and reducing the pressure on the guide rail working surface. The unloading force is generally taken as about 2/3 of the total gravity acting on the moving parts.

Online inquiry